Caliber: DN 40~200mm

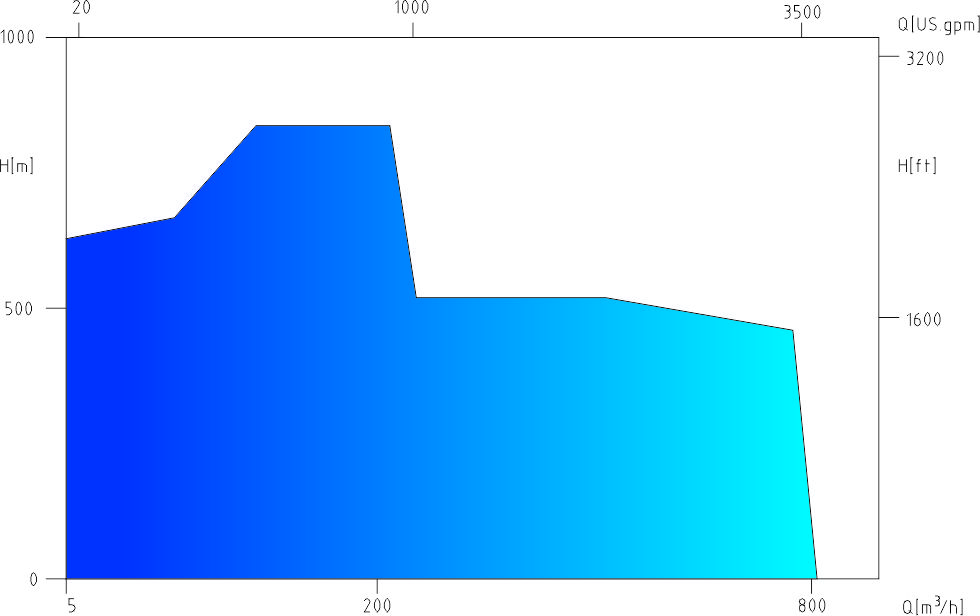

Flow rate: Q ~800 m3/h

Head: H ~ 800m

Temperature: T -180~+180℃

Design pressure: P ~10MPa

Refinery transport clean or slightly polluted, low or high temperature

chemically neutral or corrosive liquids

Oil refinery/petrochemical plant/power plant/low temperature engineering

Pipeline booster/offshore oil production platform/liquefied gas engineering

The vertical barrel pump is a multi-stage, radially split type, and has a casing. The first stage impeller is generally a suction impeller. The axial thrust is borne by the radial-thrust ball bearing. In case of a large pressure difference, the axial thrust is balanced by the balancing drum. The casing only bears the pressure at the suction opening. The length of the casing and the mounting depth of the pump depend on the requirements for NPSH cavitation performance.

If the pump is mounted on a container or connected with a pipe flange, the casing may not be required.

The bearings are lubricated with thin oil, with an independent internal circulation and automatic lubrication system. The hydrodynamic journal bearing is located at the suction opening end of the pump. When the pump is mounted at a certain depth, the pump shaft has an intermediate support, and the support is lubricated with liquid. The shaft seal is in the following forms: single-face mechanical seal and tandem mechanical seal, plus a cooling, flushing or sealing fluid system.

The suction pipe and the discharge pipe are located on the upper part of the mounting flange, at an included angle of 180 degrees. Other layouts are also acceptable.

The motor drives the pump through a flexible coupling. Viewed from the drive end, the pump rotates counterclockwise.

WeChat official account

WeChat official account